#Brown #Manufacturing #Mascot #Powder #Compacts #History #Heritage

.

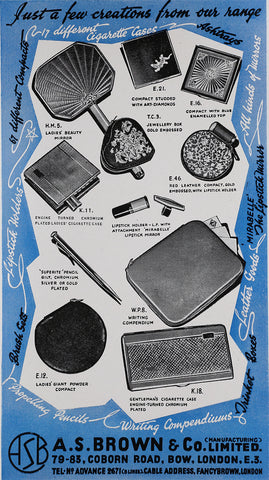

The maker of the Mascot brand of powder compacts was known as A. S. Brown & Co. (Manufacturing) Ltd. Their premises were located at 79-83 Coborn Road, Bow, London, E3. Telephone: Advance 2671 (3 lines). Cables: Fancybrown, London.

A. S. BROWN & CO. MANUFACTURING PREMISES BOW LONDON E3

Following the end of WWII the firm switched from producing aircraft components to making powder compacts and fancy goods. A.S. Brown signed its powder compacts in a variety of ways, for example, ASB, ASB Mascot or Mascot. Some vanities were not signed. These compacts were stamped with a crown symbol or a blank oblong cartouche. Usually the puff would bear the brand name but when used this was worn away. This firm was particularly well known for producing novelty powder compacts in the early and mid 50s. The company bought out one of its main British rivals, Kigu Ltd., in the early 1980s, before being taken over itself by Laughton & Sons Ltd., the owners of the Stratton brand.

In 1947 the company was listed as a British Industries Fair exhibitor. The catalogue entry is as follows:

Manufacturers of High Class Metal and Leather Powder Compacts; Cigarette Cases; Ashtrays; All Kinds of Mirrors; Imitation Leather Goods, Trinket Boxes; Zipp Writing Compendiums; Propelling Pencils; Brush Sets; Lipstick Holders; Compacts; Picture Frames; Table Mats; Novelties, etc. (Fancy Goods – Olympia, 1st Floor, Stand No. F.1851)

1947 A.S. BROWN & CO. (MANUFACTURING) LTD ADVERTISEMENT

Vintage advertisements are so informative. We can see the products they were making at the time and also the location of the firm’s premises.

The advertisement above shows goods (left to right, top to bottom)…..

H.M.5. LADIES BEAUTY MIRROR, E.21 COMPACT STUDDED WITH ART. DIAMONDS, E.16 COMPACT WITH BLUE ENAMELLED TOP,

K.11. ENGINE TURNED CHROMIUM PLATED LADIES’ CIGARETTE CASE

T.C.3. JEWELLERY BOX GOLD EMBOSSED

LIPSTICK HOLDER – L.F. WITH ATTACHMENT ‘MIRABELLE’ LIPSTICK MIRROR

E.C.46. RED LEATHER COMPACT GOLD EMBOSSED, WITH LIPSTICK HOLDER

‘SILVERITE’ PENCIL GILT, CHROMIUM SILVER GOLD PLATED

W.P.8. WRITING COMPENDIUM

E.12. LADIES’ GIANT POWDER COMPACT

K.18. GENTLEMAN’S CIGARETTE CASE ENGINE TURNED CHROMIUM . PLATED

At this time the company made 17 different styles of cigarette cases and 67 styles of powder compacts. A. S. Brown also manufactured lipstick mirrors which they named the Mirabelle, trinket boxes, brush sets, ashtrays, writing compendiums and propelling pencils.

1951 A S B ADVERTISEMENT

By 1951 the company was manufacturing over 200 different styles of powder compacts.

Some of their most gorgeous creations were adorned with Lucite.

ROMANTIC THEMED LUCITE MASCOT POWDER COMPACT

A remarkably beautiful 1950s Lucite Mascot brand loose powder compact. The gilded lid and base have splendid engine turned designs. Set atop the lid is a clear heart shaped Lucite dome which is protecting a delightful little pink rose on a background of golden tin foil. The composition of this vanity makes it an ideal tin (10th) wedding anniversary gift. Lucite is a luxury thermoplastic, making this item also suitable as a first anniversary gift. The inner lid is stamped with the Mascot brand crown.

MID-CENTURY FLORAL LUCITE LOOSE POWDER COMPACT

The Lucite loose powder shown above was crafted in the 1950s by A. S. Brown. The lid and base are engraved with guilloche engraving. The Lucite dome shields a charming Lucite floral display in vibrant crimson, azure blue and emerald green, all set atop glittering golden tin foil. The inner lid is signed Mascot A S B. The mirror bezel is signed MADE IN GREAT BRITAIN.

The firm promoted itself as The World’s Premier Makers of Souvenir Compacts. The compacts were decorated with maps and views of iconic and famous cities and tourist attractions, both within the UK and around the world.

PICCADILLY CIRCUS MASCOT SOUVENIR COMPACT

The charming 1950s powder compact pictured above is suitable for use with loose face powder. The pictorial inlay is delightful. It depicts the statue of Anteros in Piccadilly Circus, which many people mistake for Anteros’ brother, Eros. The scene is superbly well preserved having been well protected by the cellulose acetate lid. Around the pictorial inlay is a gilt border. The inner lid is signed ASB MADE IN ENGLAND. The interior of the compact is typical of the Marlene loose powder compacts.

SCARCE MASCOT HANDBAG COMPACT WITH SEQUINED MATERIAL

SCARCE MASCOT HANDBAG COMPACT WITH SEQUINED MATERIAL

An absolutely divine mid-century vanity! This sequin set 1950s Mascot handbag shaped powder compact has not been used. The brass was lacquered by the maker and so it will not need to be cleaned. The lid and base are fitted with the original elegant black patterned sequin set material. The mirror bezel is stamped MADE IN GREAT BRITAIN. The inner lid is stamped with the trademark Mascot brand crown stamp. The unused sifter and puff are present. The puff is signed Mascot A S B. Measures 7.5 cm long x 6.5 high. Weighs 93.1 grams.

LIMITED EDITION MILITARY SOUVENIR NOVELTY COMPACT

This is a military compact made to honour the Cyprus Regiment. This regiment was created on 12 April, 1940 by the British Government during WWII. It was mostly made up of volunteers from the Greek Cypriot and Turkish Cypriot communities. It also included other Commonwealth nationalities. The shield is charged with two lions passant guardant which is the badge of the Cyprus Regiment. The compact has a super engine turned design with Cyprus shown in great detail – all the major destinations inscribed on the map. At the bottom a scroll inscribed CYPRUS & two cloud shaped cartouches – one engraved with a tall ship at sea & the other with St. Sophia Cathedral.

MASCOT P&O POWDER BOWL

ASB were commissioned by prestigious shipping lines to make gifts for their first class passengers. Typically, ladies would be gifted vanities with the shipping line logo emblazoned on the lid. These delightful souvenir vanities became treasured possessions and special reminders of the luxurious voyage which may have been a once in a lifetime cruise. A printed gift card included with the gifts read as follows:

With the Compliments

of the

Chairman and Managing Directors

at the

P. & O. S. N. Company

The Peninsula & Oriental Steam Navigation Company originally operated on the Iberian Peninsula. In 1844 P&O became the first company in the world to offer passenger cruises. The company became very powerful, bought out other operators & built faster & more luxurious vessels that travelled to the most exotic locations.

THE PENINSULA & ORIENTAL STEAM NAVIGATION COMPANY LOGO

The powder bowl bears the P & O coat of arms and the inscription –

Quis nos separabit (who will separate us)

The enchanting coat of arms is decorated with a lion, an elephant, a dragon & a kangaroo which represented their considerable interests in Britain, India, China & Australia.

ASB were perhaps most famous for their novelty handbag shaped powder compacts which included musical ones.

Click to see a musical Mascot handbag powder compact.

Musical novelty compacts are highly desirable & can command high prices at specialist auctions. Powder compacts are described as being a novelty when they resemble something other than a powder compact or have a different function. Mascot were always on trend & the handbag shaped powder compacts were such a fashionable musical powder box in mid-century Britain. The makers became famous for producing a wide variety of loose powder compacts in the shape of handbags or suitcases.

1950s ASB Handbag Novelty Powder Compact

1958 ADVERTISEMENT

This advertisement illustrates the styles of handbags which were popular during the 1950s. The ASB handbag compact shown above resembles the Attache style handbag in the advertisement – second left middle.

The major vanities manufacturers at this time also produced accessories for well known high street names such as Boots The Chemist, H. Samuel and large department stores. Jarrett, Rainsford & Laughton Ltd. (from 1958 known as Laughton & Sons Ltd.), Kigu Ltd. and A.S. Brown supplied vanities and accessories to high street outlets. Usually these commissioned powder compacts and gift sets were not signed by the manufacturers, as the retailers wished to market them as their own. However, the models are exact mm to mm unsigned models of those that the manufacturing concerns already produced and so we can assign their original origins.

We adore the set shown below, as it solved a mystery for us.

UNUSED MASCOT PERFUME ATOMISER AND COMPACT SET

This super set was exactly the same as sets made for Boots The Chemist, albeit with a different exterior decoration. The vintage perfume atomizer and refillable pressed powder compact were made by A. S. Brown in the 1960s. The compact is suitable for all standard (67 mm diameter) pans of face powder. For example: Rimmel Stay Matte, Max Factor Creme Puff and Miss Beauty. We often wondered who manufactured the Boots brand compact mirrors and we now know that this style was made by A. S. Brown.

NOTE THE SAME STYLE & IDENTICAL POWDER WELL INSERT

The compact in this set is the exact same model and the original leaflet included is also identical, except for the brand name. On the gift set sets destined for Boots The Chemist you will see Boots where you see the Mascot signature on the instruction leaflet which also serves as a protective paper insert in the powder well. The perfumes contained in face powder can be damaging to metal. The paper insert forms a protective barrier. This Mascot branded powder compact and atomizer set is presented in the original box. Both items are decorated with an eye-catching blue and black design. The brass is lacquered and so it will not tarnish or need to be cleaned. The little atomizer is so delightful! The top of the atomizer is satinized and this textured surface is so attractive. The original silk topped puff is in place. The base of the compact has a gold spiral design. The compact measures almost 3″ and weighs 58.3 grams. The atomizer measures 3″ diameter and weighs 26.8 grams.

Below you will see patents granted to the firm which include those for perfume atomizers.

The gentleman who invented patented devices for the firm was called Ernest Peter Chrome. Whether or not he was a company director we do not know.

Please note that all the patent descriptions appear here unedited.

Inventor CROME ERNEST PETER

GB753169A

Improvements in or relating to powder compacts or the like

Abstract

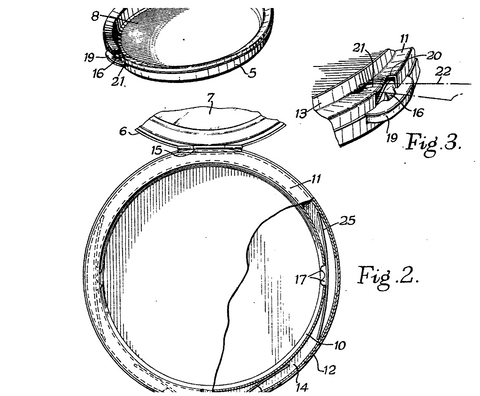

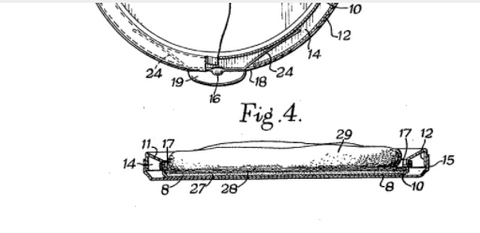

753,169. Catch fastenings. BROWN & CO. (MANUFACTURING), Ltd., A. S. April 7, 1955 [May 3, 1954], No. 12840/54. Class 44. [Also in Group XVII] A fastening on a compact comprises a fingerpiece 19 urged outwardly by spring elements 24 to cause a catch 16 to engage a depression, not shown, in the lid 6.

We, A. S. BROWN & COMPANY (MANU-

FACTURING) LIMITED, a British Company, of 79–83 Coborn Road, Bow, London, E.3, do hereby declare the invention, for which we pray that a patent may be granted to us, and the method by which it is to be performed, to be particularly described in and by the

following statement: –

The present invention relates to powder compacts or the like, and is particularly, but not exclusively, concerned with the kind of powder compact which is adapted to accommodate a removable powder refill consisting of a solid or semi-solid block of for example cream powder or compressed powder in a shallow dished container of metal, rigid synthetic plastic material or the like.

It is an object of the present invention to provide an improved powder compact of the kind referred to which is reliable and convenient in use, more particularly in regard to the manner in which it detachably holds the refills, and which is of a construction permitting economical manufacture while at the same time facilitating the incorporation of refinements which are usually associated with more expensive powder compacts. Such refinements include, for example, the provision of a spring catch for the lid of the compact which is operated by a thumb-piece and the elimination of sharp edges round the rim of the bottom part of the compact.

A further object is to provide a powder compact of the kind referred to which also lends itself particularly well for use when required as a conventional powder compact to contain ordinary face powder.

With these objects in view, the bottom part of the improved powder compact according to the present invention comprises a relatively large outer dished casing and a relatively small inner dished casing which is adapted to accommodate the refills and has its top rim bent outward and then verti[Price 3s. Od.] cally downward, the downwardly bent part being located against the side wall of the outer casing and the annular space between the inner and outer casings accommodating resilient means adapted to urge gripping elements, projecting through apertures in the wall of the inner casing, into engagement with the sides of said refills.

It will be appreciated that the same annular space that accommodates the resilient means associated with the gripping elements can also be utilised to accommodate the spring of a spring catch for retaining the lid of the powder compact in the closed position.

The inner casing may be shaped so as to provide a stepped ledge a short distance above its base, which ledge is adapted in use to support the refills. with their bottom surfaces spaced from the bottom of the inner casing. Consequently if, as often occurs, a refill inserted into the compact has its bottom surface partly coated with an adhesive, the bottom surface of the refill and inner casing will not stick together and thereby render difficult the removal of the refill when empty.

The outwardly bent part of the rim of the inner casing is advantageously formed with a depression between the lid catch and the well for the reception of the refill, which depression exposes part of the outer wall of a refill in the compact for engagement by a pointed object such as a nail file introduced for the purpose of prising out the refill.

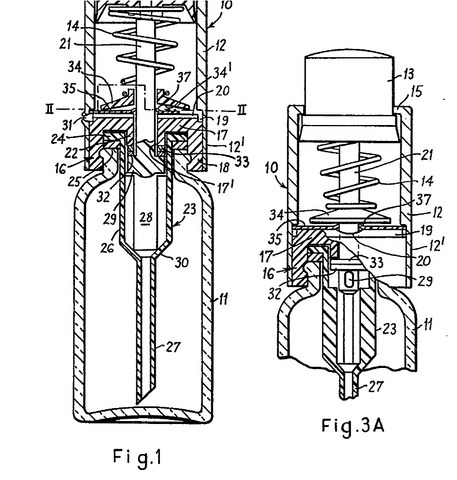

A preferred form of powder compact according to this invention will now be described by way of example with reference to the accompanying drawings, in which: Fig. 1 is a perspective view of a powder compact and an empty powder refill container, Fig. 2 is a partly sectioned fragmentary plan view of the powder compact with the 753,169 PATENT SPECIFICATION

Inientor:-ERNEST PETER CROME H i Date of filing Complete Specification: April 7, 1955.

gi 3 Application Date: May 3, 1954. No. 12840/54.

Complete Specification Published: July 18, 1956.

Index at Acceptalice:-Classes 18, A(1W: 6H2); and 44, BE3A1B.

COMPLETE SPECIFICATION.

Improvements in or relating to Powder Compacts or the like.

753,169 lid open and with the refill container removed, Fig. 3 is a fragmentary perspective view illustrating the manner in which a refill can be removed from the powder compact with the aid of a nail file, and Fig. 4 is a vertical section showing how the powder compact can be used to contain ordinary face powder under a powder sifter.

The same references are used to indicate similar parts in all the figures of the drawings.

The compact, which is of the conventional flat substantially cylindrical shape, has a bottom outer casing 5 and a hinged lid 6 provided in known manner with an interior mirror 7. Fitted within the said outer casing is a removable dished inner casing 8 of somewhat smaller diameter. The inner casing 8 has a vertical side wall 9 which is stepped close above the base to provide an annular ledge 10 and has its upper rim bent outward at 11 at a slight upward inclination and then vertically downward at 12 for a distance considerably less than the depth of the well of the said inner casing 8. The downwardly bent part 12- is a push fit within the side wall of the outer casing 5.

– The interior diameter of the inner casing 8 above the annular ledge 10 is approximately the same as the external diameter of the container 13 of a standard powder refill, so that the latter, when inserted, will rest on the said ledge 10.

Between the side wall 9 and the downwardly bent rim part 12 of the inner casing is an annular space 14 which accommodates, on the side of the compact remote from the hinge 15, part of a spring catch 16 for the lid 6. The same annular space 14 also accommodates, in positions on both sides located midway between the lid catch 16 and the hinge 15, two spring-loaded gripping members having jaws 17 which project through apertures in the side wall 9 of the inner casing. These gripping members are adapted for detachably holding the container 13 of an inserted refill.

0 The bottom part of the outer casing is cut away at 18 -(Fig. 2) to accommodate a thumb-piece 19 which is rivetted to, and serves for operating, the lid catch 16; and the inclined outwardly bent part 11 of the inner -casing is likewise cut away at 20 (Fig. 3) to accommodate the lid catch 16 itself.

A depression 21 is- formed in the inclined outwardly bent part 11 of the rim of the inner casing 8 between the catch 16 and the well for the refill, so that part of the outer wall of the contamier 13 of the latter is exposed for engagement by a pointed object such as a nail file 22 (Fig. 3) in order to enable it to be prised out of the compact when empty.

The lid catch 16, which co-operates with an inwardly bent part 23 (Fig. 1) on the rim of the lid 6, is formed integrally with a bowed leaf spring 24, the two ends of which are adapted to bear against the wall 9 of the inner casing 8; and the thumb-piece 19 70 already referred to is rivetted to this integral catch and leaf spring member.

Each of the two gripping members 17 for the refills is constituted by a partly cut-away lug (see Fig. 2) which is formed integrally 75 on the lower edge of a straight leaf spring such as 25 and projects at right angles to the plane of the latter through the corresponding aperture in the wall 9 of the inner casing 8. The ends of the straight 80 leaf spring 25 bear against the downturned flange 12 of the upper rim of the inner casing -8. The jaws 17 of the gripping members may have bevelled top surfaces (not shown) which, together with a radiused 85 bottom edge 26 on the powder refill container 13, enable the latter on being inserted into the powder compact to depress the gripping members.

Due to the disposition of the gripping 90 members in relation to the top edge of the refill, the said gripping members are wholly concealed and are prevented from damaging the powder puff in use.

The inclined outwardly bent rim part 11 95 of the inner casting 8 not only improves the appearance of the compact when open, by giving it a look of solidity and richness, but also assists the wiping action of the powder puff and increases the life of the latter 100 by eliminating sharp edges from the rim surrounding the refill.

If it is desired to use the powder compact for ordinary face powder, without the abovementioned refills, a quantity of face powder 105 27 (Fig. 4) is poured into the well of the inner casing 8. A powder sifter 28 is then pressed down over the powder until it rests on the ledge 10 and is retained by the gripping members 17, after which a powder 110 puff 29 or the like can be inserted over the powder sifter 28.

Improvements in powder compacts and the like

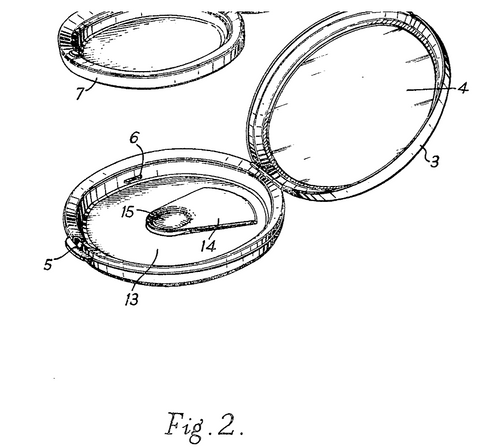

Abstract

835,485. Powder compacts. BROWN & CO. (MANUFACTURING) Ltd., A. S. Aug. 20, 1958 [Nov. 13, 1957], No. 35445/57. Class 18. In a powder compact for either a loose or a cream powder refill 8 the base of the outer container is formed with an aperture 11 (not shown) to allow a finger to be inserted and press on a substantially flat resilient sheet metal tongue 14 to raise the refill 8 to enable it to be withdrawn. The outer container has a hinged lid 3 and is formed with a false bottom 13 out of which the tongue is cut with its free end 15 closing the aperture 11 and slightly dished in shape. The refill 8 is retained in place by resilient catches 6 which engage an annular groove 7 on the refill.

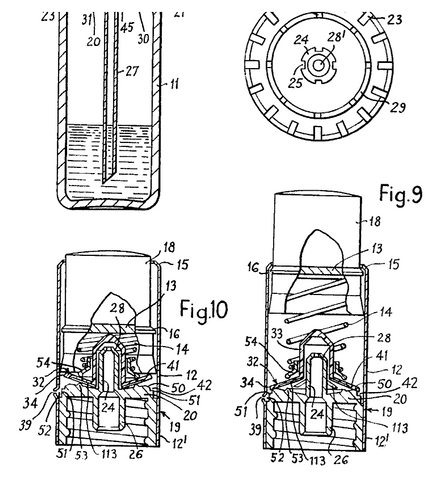

PATENT GB1298067A IMPROVEMENTS IN AND RELATING TO ATOMIZERS

IMPROVEMENTS IN AND RELATING TO ATOMIZERS

Abstract

1298067 Atomizers A S BROWN & CO (MFG) Ltd and E P CROME 17 Feb 1970 [25 Feb 1969] 10113/69 Heading B2F Liquids are sprayed by a device comprising a cylinder 12 in which there is a piston 13, the cylinder having an extension 12′ for attachment thereto of a liquid container, a transverse partition 17 separating the part in which the piston moves from the extension, a diaphragm 35 overlying the partition on the cylinder side, which diaphragm is flattened against the partition on the compression stroke of the piston and its centre moves away on the suction stroke, forming a chamber between the diaphragm and the partition (Fig. 3C) into which liquid is drawn through a connection with the liquid container. This liquid is sprayed out on a further compression stroke of the piston via an outlet in the chamber to an orifice 31 in the cylinder. In the embodiment shown the chamber is further defined by a conical member 34, the diaphragm touching the underside of this when the chamber is at its maximum size, the conical member being held against the diaphragm, which is cut away at one side to allow entry for compressed air (Fig. 2), and the partition by a spring 14, which spring is compressed on the compression stroke of the finger actuated piston 13. The container 11 for the liquid is screwed into a skirt extending down from the partition, the container holding in place a tubular member 23 extending into the container. A stem 21 extends from the piston 13 through holes in the conical member, diaphragm and partition into a wide bore section 26 of the member 23, there being a gap between the stem and the partition for passage therethrough of liquid to the chamber formed by the diaphragm, and seals 32, 33 resting on vanes 29 on the stem 21 to seal. this gap when the piston is not depressed. There may be grooves in part 26 of the member 23 so that the piston may only be depressed when vanes 29 are in alignment with the grooves, thus the piston may be locked in its non-depressed condition. The passage of the liquid out of the chamber formed by the diaphragm and partition is by radial grooves 20 and a annular groove 19 (Fig. 2) which communicates with the orifice 31. The atomiser may be used for cosmetics, medical or industrial purposes.

PATENT GB1336471A FOR PERFUME ATOMISER

If the diameter of the lower edge of the collar 54 is equal to that of the ridge 53, the spring 14 has no effect on the inherent resilience of the membrane to

The annular rib 35 which is provided in the previous embodiments on the upper side of the membrane 41 for the purpose of locating the spring 14 can be dispensed with as the spring is now located by the collar 54.

It has been found that the ratio between the area of the orifice 39 and the crosssectional area of the space

It is preferable for the vertical position of the orifice 39 to be closely adjusted relative to the position of the step 51. in order to obtain the desired mixture in the spray.

This latter adjustment is simplified if the side wall of the partition

The atomizer head according to the invention has a number of important advantages.

First of all. as the container is not pressurised, no separate sealing means needs to be provided and a stem projecting from the atomizer head and on which these sealing means would have to be mounted becomes unnecessary.

Elimination of the stem makes it further possible to use a relatively slender and narrow-bore syphon tube of uniform diameter projecting from the container 11 into the atomizer head. Such a tube may be inserted with a close fit into the boss

Fig. 1. Alternatively, it may he inserted into the container 11 formed for this purpose with a neck which has a

Other

Since the syphon tube is not evacuated at each down stroke of the piston, an atomizer of which the head according to the invention is fitted may be used upside down, i.e. with the container above the atomizer head, until the syphon tube is exhausted.

The use of a relatively slender syphon tube makes it possible for the container to be almost completely filled with liquid without risk of waste by overspill after the syphon tube has been inserted.

Finally, in the absence of pressure air in the syphon tube there is no risk of air locks being formed therein which would impede the passage of liquid up the syphon tube.

It is understood that the terms “upper” and “lower”

1. An atomizer head for a spray atomizer, said atomizer head comprising an air

2. An atomizer head according to Claim

1 in which a compression spring is inserted between said piston and said membrane.

3. An atomizer head according to Claim 1 in which the deflection of said membrane from its first to its second position is effected by the compression stroke of said piston and its deflection from its second to its first position is effected by the suction stroke of said piston.

4. An atomizer head according to Claim 1 in which said membrane is in both positions in the shape of a frustrum of a cone, pointing towards said piston when said membrane is in its first position and away from said piston when said membrane is in its second position.

5. An atomizer head according to Claim 4 in which the surface of the partition is formed on its piston side with a ridge which during inversion of the membrane acts as its fulcrum.

6. An atomizer head according to Claim 5 in which a number of slits are provided in said ridge as passageways between the mixing chamber and a space in the cylinder surrounding said chamber.

7. An atomizer head according to Claim 1 in which a sealing ring supported on said partition seals said chamber from a space in the cylinder surrounding said chamber.

8. An atomizer head according to Claim 7 in which said sealing ring is fitted into a groove formed between two ridges on the piston side of said partition.

9. An atomizer head according to Claim

10. An atomizer head according to Claim 1 in which radial grooves are formed in said membrane.

11. An atomizer head according to Claim 10 in which said grooves are cut into the side of said membrane which faces said

14. An atomizer head

15. An atomizer head according to Claim 14 in which the surface of the partition facing said side wall has a slope.

16. An atomizer head according to Claim 15 in which oblique slots are provided in the sloping surface of said partition.

17. An atomizer head according to Claim 14 in which the periphery of the partition is formed with a step.

18. An atomizer head according to Claim 1 in which a passageway is provided, to lead from said container through the centre of said partition into said chamber, said passageway being closed by said diaphragm valve when said membrane is in its second position.

19. An atomizer head according to Claim 18 in which said diaphragm valve has a centre part which is in the shape of an inverted cup and is joined to said membrane at its inner rim, said partition having a central hollow boss which enters said cup-shaped centre part, a passage in said boss for communicating at one end with said container and at the other end with a radial space left between said cup-shaped centre part and said boss.

20. An atomizer head according to Claim 19 in which longitudinal grooves are provided in the exterior of said boss or in the interior of said cup-shaped centre part.

21. An atomizer head according to Claim 1 in which a central hollow boss is formed on the side of said partition facing away from said piston.

22. An atomizer head according to Claim 1 in which a syphon tube is adapted to have a fluid-tight fit in a central hollow boss formed on said partition, the syphon tube when fitted to said boss being adapted to enter said container.

23. An atomizer head for a spray atomizer substantially as described with reference to Figs. 1 to 5 of the accompanying drawings.

24. An atomizer head for a spray atomizer substantially as described with reference to Fig. 6 of the accompanying drawings.

25. An atomizer head for a spray atomizer substantially as described with reference to Fig. 7 of

26. An atomizer head for a spray atomizer substantially as described with reference to Figs. 9 and 10 of the accompanying drawings.

27. A spray atomizer comprising an atomizer head according to any one of the preceding claims and a liquid container attached to said atomizer head.

More information about Lucite and Lucite powder compacts.

More information about music boxes.